|

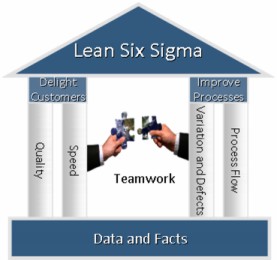

What Is Lean Six Sigma?Not Just Doing Better, But Doing Better ThingsBefore we start to address the question "what is Lean Six Sigma?" it will help to clarify our terms if we look briefly at the differences between Lean and Six Sigma. Lean is focused on improving the flow of a process by reducing wastage and improving cycle time, it is about standardisation, logistics and cost reduction. Six-sigma is focused on reducing process variation by the collation of detailed data and the application of statistical tools within the context of a project based methodology - typically DMAIC, for process improvement. The following graphic highlights the comparisons and contrasts of: What is Lean Six Sigma? -> Kaizen vs Lean vs Six Sigma - PDF

Lean and Six Sigma - what is the difference?

So... what is Lean Six Sigma?I am sure that it won't surprise you to learn that Lean Six Sigma is a combination of Lean and Six Sigma methodologies and approaches. As discussed above, the focus of Lean is on cost reduction via process optimization. Six Sigma is a more complex approach that in summary seeks to meet customer requirements and stakeholder expectations, based on quality improvements that are derived from measuring and eliminating defects. Lean Six Sigma brings together the philosophies, principles and tools of both with the higher goal of greater effectiveness, not just efficiency - it's not just about "doing things better but doing better things" - a subtle but powerful distinction! From this history of lean manufacturing to pros and cons, this in-depth guide explores everything you need to know about lean manufacturing: The Ultimate Guide to Lean Manufacturing

According to IBM Global Business Services: "In the past, companies used Lean Six Sigma primarily for operational improvement – refining existing processes to reduce costs, improve performance and provide better customer value. However, dramatic upheavals in the competitive marketplace are prompting business change on a much more massive scale. Companies must innovate, not just improve. Despite its heritage, Lean Six Sigma is wellsuited for this step change in target and scope. The leading companies we studied are proving that the Lean Six Sigma approach has applications far beyond process improvement; they are using it to innovate in all areas of their businesses – their operations, their products and services and even their business models." Read the full report here: Driving operational innovation using Lean Six Sigma - PDF

Additional Resources on Six SigmaSteps In Six Sigma Methodology

|